Dewas - 455001 M.P. INDIA

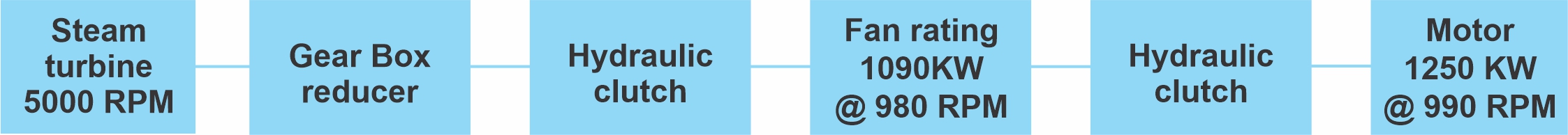

Indogulf Fertilizer - Jagdishpur have FD Fan in their ammonia plant. This is a very critical Fan in the manufacturing process. The fan is rated for 1090KW at 980 RPM. The fan has twin-drive alternative through a steam turbine on one end and electric motor of 1250KW - 990 RPM drive on the other end as stand by. The drive arrangement has a hydraulic clutch in between the fan and turbine and as well as motor and fan to decouple one of the drive when the other is used. The drive arrangement is shown below :-

The fan was generally driven by the steam turbine at 983 RPM. The fan capacity is too large at 983 RPM and which resulted in operation of fan with damper closed condition of 70-75% to meet the process flow and system requirement. Also problem of high vibration level was felt when operating fan at 980RPM with damper 70% closed. At the same time regulation of gas flow rate was difficult with damper control resulting into erratic operation and affected adversely the other parameters and controls of the plant.

The hydraulic clutches were a source of continuous problem with frequent break downs resulting in production loss frequently.

Indogulf set the task to solve this perennial problem and find a suitable drive solutions. The technical team of Indogulf took the challenge to solve the complex and difficult problem and examined various alternatives and possibilities. The task also included the objective to drive the fan by motor and at the same time to save energy. There were severe space and layout constraints. Indogulf team took the challenge of finding the drive solution with high spirits and confidence.

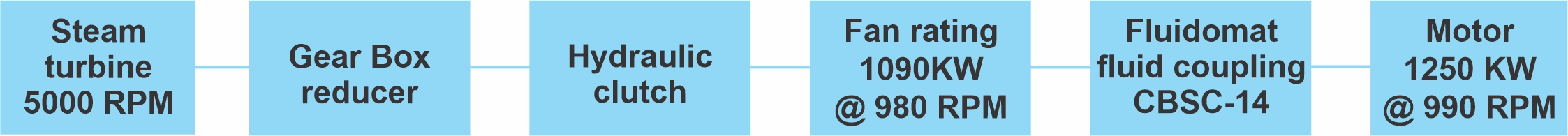

Fluidomat was invited to examine and provide the solution through their Fluid Coupling. Fluidomat team studied the technical and operation details and took the challenge to offer a solution within space and layout constraint. After detailed investigation and innovative ideas Fluidomat offered the solution to Indogulf.

Fluidomat offered their custom built scoop control variable speed coupling model CBSC-14. The Fluidomat fluid coupling was custom built to fit into available space. The oil tank, oil cooler, oil pump and filter were placed at a lower level to overcome the space constraint. Duplex system of oil pump, cooler and filter were provided. The coupling provided with pneumatic actuator with automatic control provides stepless speed variation in range of 1000 to 250 RPM. The coupling was installed in July 2003.

Indo Gulf removed the clutch from the motor side and installed the Fluidomat coupling in its place. The revised drive layout is as under.

Fluidomat suggested Indo Gulf to open the damper fully and reduce the fan speed to get substantial energy saving.

Indo Gulf discovered that to meet the flow requirement, they could operate the fan between 400-600 rpm and keep the damper fully open with automatic speed control.

With the low speed operation of the fan 400KW of power is saved. The power saving of 400KW works out to a tremendous saving of RS. 15000000/- (Rupees Fifteen Million) per annum on 7500 hours working p.a at energy rate Rs. 5/- per unit. Besides with low speed operation of the fan, the fan life, bearing life and noise level etc. are greatly improved . The problem of vibrations and gas flow rate control is fully solved.

Fluidomat thanks Indo Gulf for providing the opportunity and adding one more feather in cap of Fluidomat in their endeavour of providing drive solutions and energy saving which is so important to our country and the ecology.