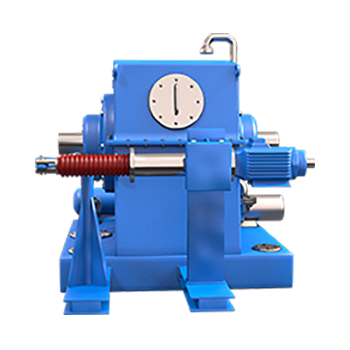

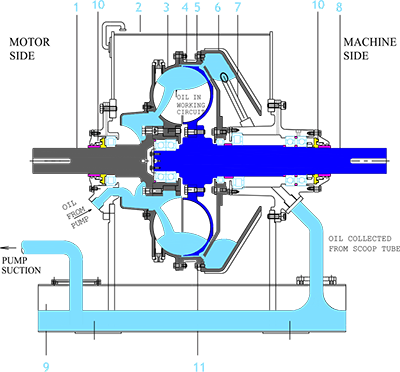

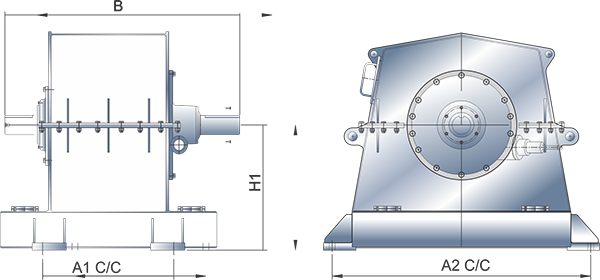

- Self supported statinary housing, hence no weight experienced by driving or driven shafts and does not load motor and machine bearings.

- Rugged design for all site conditions.

- Rotating mass is not exposed, hence, no hazzards of accidents.

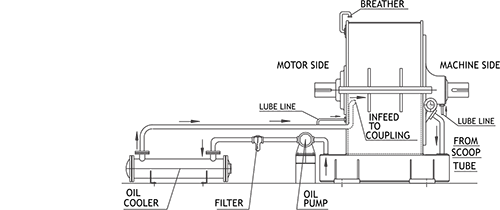

- Easy mountings of various controls, oil connections, sensors etc.

- Higher misalignment capacity and choice of flexible couplings.

- Easy maintenance and accessibility by opening top cover.

- Continuous declutching possible.

- Very low vibration and noise level.

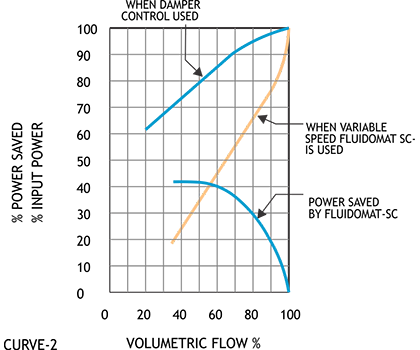

- Ease of adopting various type of control and compatible with them.

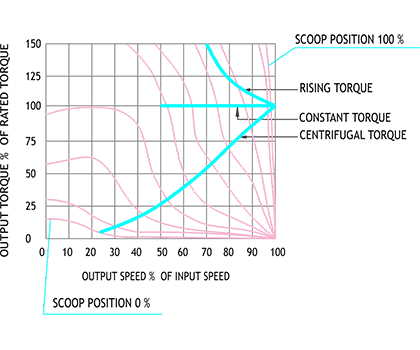

- Scoop tube position can be governed very easily for speed control.

- Easy operation of scoop tube in auto or manual mode.

- Labyrinth seals on shaft ensures no leakage from shaft ends.

7C-8J, I. S. Gajra Industrial Area - 1, A.B. Road,

Dewas - 455001 M.P. INDIA

Email info@fluidomat.com

Email info@fluidomat.com

Dewas - 455001 M.P. INDIA