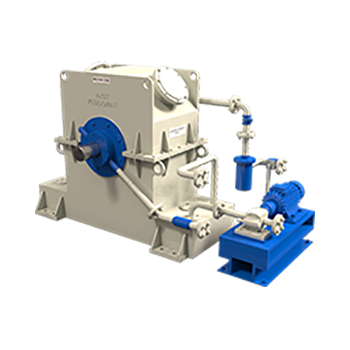

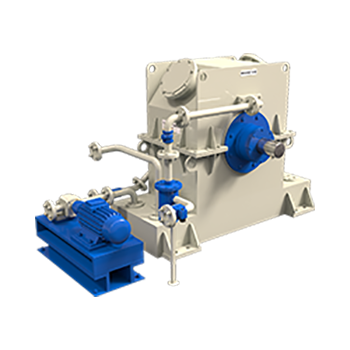

The FNCT couplings can be used in variety of applications as a startup duty and controlled and smooth acceleration of heavy masses

and inertia.Ideally suited for Belt and Pipe Conveyor application.

Typical applications include:

-

Belt conveyor soon underground mines or on surface installations.

-

Pipeconveyors.

-

Crushers.

-

Balland Rod Mills.

-

Shredders.

-

Armored Face Conveyors(AFC).

-

Mixers.

-

Beaters.

-

Other typical applications.

Email info@fluidomat.com

Email info@fluidomat.com